|

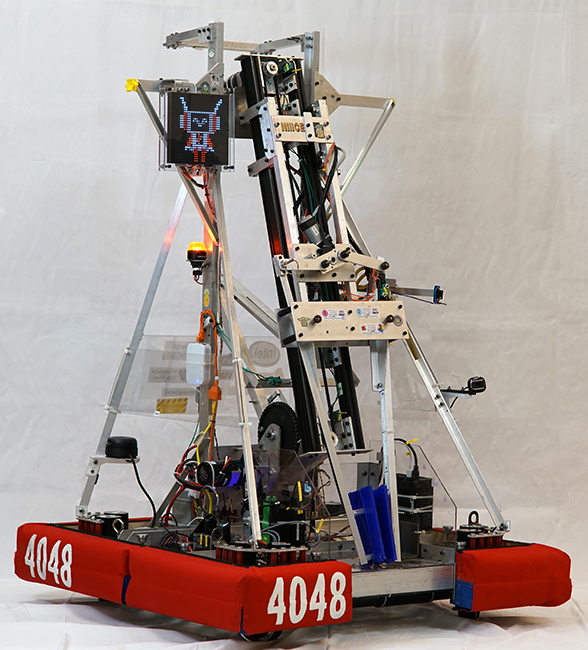

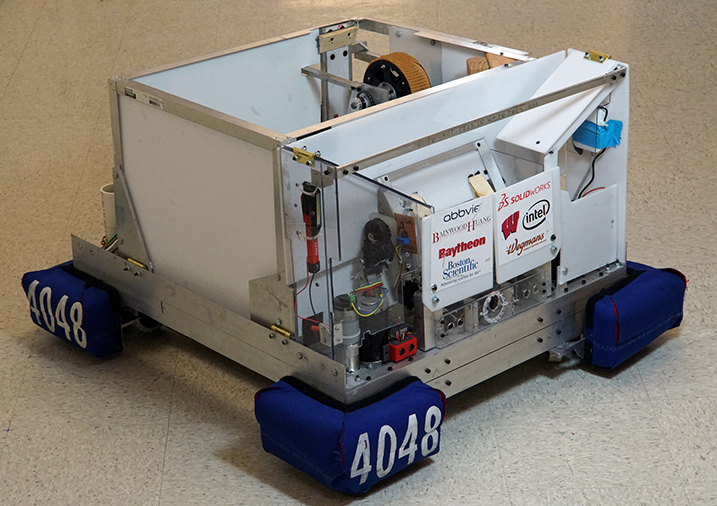

Ferbinator, Charged Up, 2023

The 2023 challenge was perfect for swerve drives. The robots have to navigate some tight spaces as well as react quickly in the open field. Driving accuracy is important in order to avoid penalties. We went with the SDS MK4 swerve modules with Neo motors. For game piece manipulation, we used an arm with a single stage extension with a pincher mechanism able to grab and hold both the "cone" and the "cube". The height of the tower was made 1/4 inch short of the maximum allowed height. For stability, the frame perimeter was set to the maximum 120 inches (30x30). For the endgame balancing act, three robots have to share an 8 ft wide platform so we added two metal pipes in our undercarriage to allow our robot to slide slightly off the edge of the Charging Station, thus reducing our use of the 8 ft by as much as 12 inches. We also had provisions for adding a lidar and 3D camera so that we could start gathering field data and learn how to do more advanced machine manipulations in the future. Lastly for communication between the driver station and the human player on the opposite side of the field, we added a 32x32 LED panel. |

|

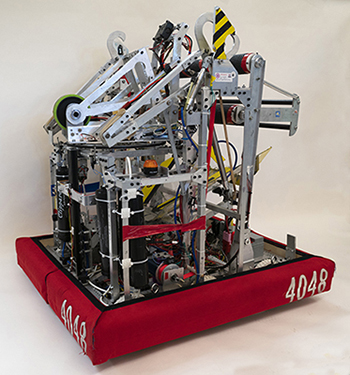

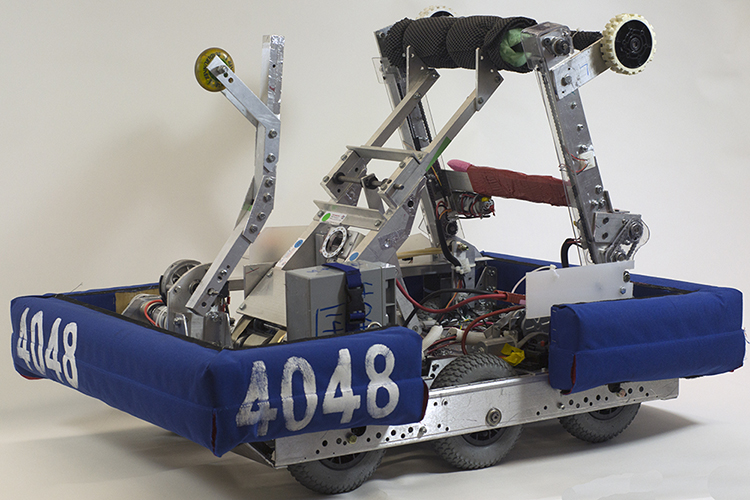

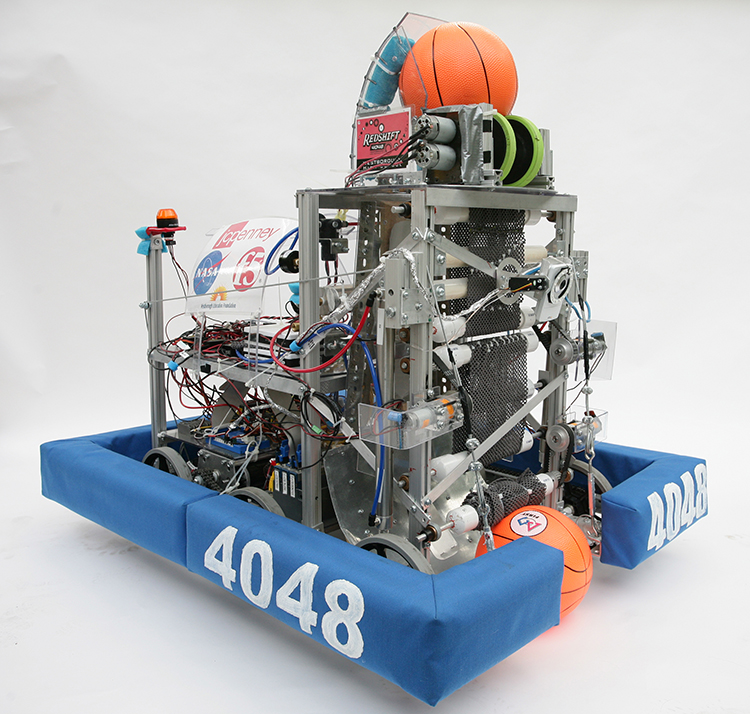

Spinister, Rapid React, 2022

Our 2022 team had a huge influx of new students (62%) including many freshman (49%). To get the chassis up and running as quickly as possible we opted to use the KOP 6-wheel drop center chassis. For the shooting mechanism we went for a vision tracking turret because we've always wanted to make one and this challenge gave all the reasons to do so. We ended up with single shot shooter fed by a pneumatically driven loader. The intake delivered one ball at a time. The climber was the last part to be completed and consisted of two individual double segmented arms, strap winches, and frame-mounted statc latches. The overall design proved to be very robust and flexible, allowing the robot to hold itself with one arm. This robot also differed from our other vehicles in our use of less metal, smaller fasteners (10-32 vs 1/4-20) and even carbon fiber in the intake to reduce weight. |

|

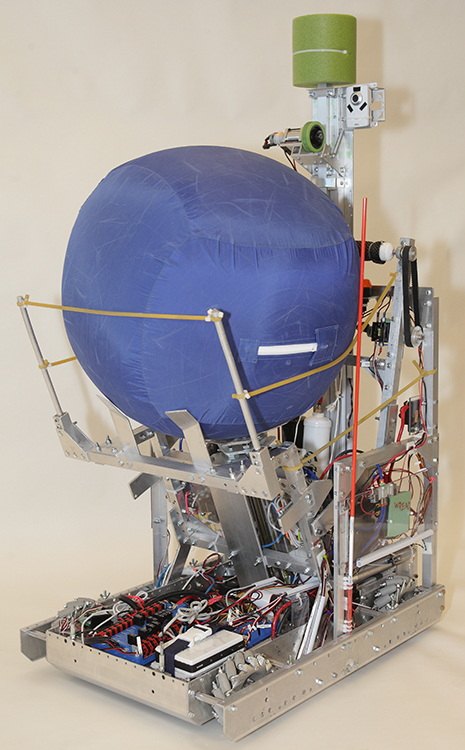

Three Point Turn, Infinite Recharge, 2020 and 2021

The 2020 challenge has the more traditional field layout where the Drive Team for a given alliance is on the opposite side of the field from the scoring area. It also features a long, protected path from one side to the other as well as ground obstacles in some parts of the field. This gave us a good reason to use a 2-speed gearbox for extra speed along the long straightaways and extra torque on defense. We went with 8 inch pneumatic tires for better control over the ground obstables. We opted to score only in the low goal and do it quickly and reliably rather than try to score higher value high goals but miss more often. An internal conveyor holds up to the 5 Fuel Cell maximum allowed. Fuel cell intake is from the ground. There is also a Control Panel manipulator device and a climber to round off the robot's feature list. Pneumatic actuators are used in the intake, climber, control panel and gear shifter. The name Three Point Turn is due to the robot's difficulty in making sharp turns. The pneumatic wheels have more friction and require more vertical separation in the drop-center alignment. The name is a play off of our 2013 robot "U-turn". Due to the COVID pandemic, there was no new robot for 2021. |

|

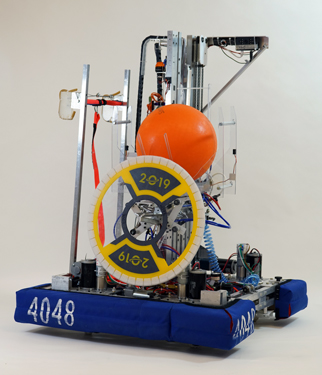

Delta77, Operation: Deep Space, 2019

This robot was originally made with a 77 inch elevator; hence the name. Due to weight issues, the 3rd stage was removed so the net height is actually lower now. Nonetheless the name stuck. Delta77 has a square chassis with an elevator offset to one corner. Four swerve drives allow any side of the robot to be the "front" a feature we put to use during the evolution of the robot as we transited from one competition to another and made improvements. In the first competition, the swivel arm was severed. This forced us to swap the front and back of the robot thereby changing the way in which we load Cargo and handle Patch Panels. A pneumatic extension for the Patch Panel mechanism replaced the swivel at the second competition. By the third competition, the climber was finally dialed in and with the aid of stilts to absorb the majority of the impact, the climber finally became an effective scoring device. Everything except for the elevator is pneumatically controlled. |

|

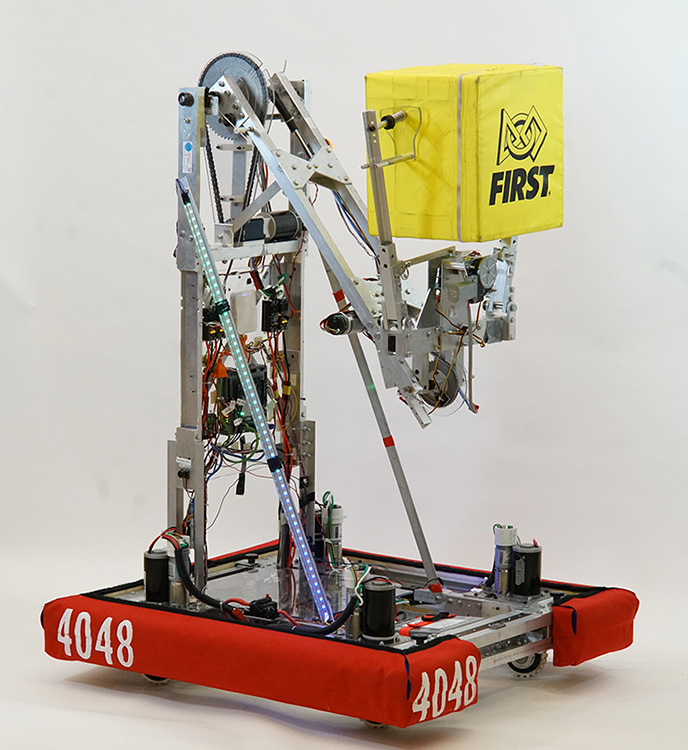

Panthera, Power Up, 2018

Panthera means "giraffe" in Latin and this robot reminds one of a giraffe. There are two versions of Panthera. The first version was used at the WPI District Event and proved to be overly complex and unreliable. That version had an intake system to control a game Cube and an arm to deliver the Cube to various heights. The arm consisted of a vertical tower, a pivoting extensible portion, a gripper to squeeze the Cube and a wrist to rotate the gripper. With the addition of four swerve drives, there were a total of 16 motors. This design was inefficient and fragile. The intake and arm were really 2 distinct units that did not integrate well. The overall cycle time to grab and place a Cube took too long. The second version used a simplified arm that replaced the intake, gripper, and extension with an elbow and pincher. This unit was lighter, quicker, and far more robust. The software changes were fairly minimal, with a lot of code now rendered obsolete. While the win-loss results may not show it, the second version of the robot performed far better than its predecessor. |

|

Satis, Steamworks, 2017

Satis was our team's first swerve drive robot. We opted for AndyMark's swerve module with 4 inch wheels; one in each corner of a roughly square robot. The chassis consisted of a climber along one edge, a "gear" placement device along the opposite edge and a ball hopper in the middle. A powered scoop ingested balls into the hopper from the ground. In the first iteration, the hopper had of a moving "floor" that would deliver the balls to the low goal. In a later iteration, a ball shooter replaced the moving floor to shoot balls at the high goal. The climber used velcro on the rope to start the winding process and worked great. The active "gear" system was difficult to align with the scoring Lift mechanism and the barn door servos mysteriously burned out. Eventually the swerve drives themselves proved to be finicky. With use, their reliability diminished and we often found ourselves driving on 3 wheels. That said, the field-centric drive software made driving extremely easy and with some work, this drivetrain will be much more reliable the next time we use it. The gear mechanism, ball shooter and climber was retired in 2017; its parts recycled for other uses. |

|

Lepus Interfector, Stronghold, 2016

Lepus Interfector (killer bunny) was a 6-wheel drop center robot with 8 inch pneumatic wheels. Pneumatic wheels were chosen to help absorb the shock from the pounding the robot took maneuvering through the various obstacles. The core of the design is a boulder shooter that load a ball from the rear and shoots out the front. The intake mechanism at the rear is a floating roller that can be raised and lowered. The shooter is a catapult powered by Vulcan springs generating 90 pounds of force. The entire robot fits under the "low bar". The front arm lowers the cheval-de-frise. There is no climber. To help cross the "rock wall", there is a steel skid plate at the leading edge of the robot. Located on the front of the shooter is a camera to help aim the robot. The trajectory has a long relatively flat curve so driving the robot to the right distance is not as important as rotating it to the correct angle. Automatic shooting was implemented and tested but never used in competition. |

|

Interstellevator, Recycle Rush, 2015

Recycle Rush had practically no defensive needs so the robot had no bumpers. The front end was a forklift. Two arms opened and closed to securely hold a crate. The arm assembly went up and down to help stack the crates. All told, it could hold 4 crates and one bin and stack 5 crates and one bin. At the rear of the robot is a bin grabber. The grabber is a fiberglass rod mounted to an aluminum head. During the autonomous period, the arm will drop the head into the bin's top opening and pull the bin forwards (in one match is also tore off the arm of a competing robot trying to grab the same bin!). Interstellevator has a mecanum drivetrain powered by four CIM motors. It was retired in 2016; its parts recycled for other uses. |

|

Scorpio, Aerial Assist, 2014

Scorpio's core consisted of a 6 piston, dual stage pneumatic ball launcher. There were 2 shooting angles also controlled pneumatically. There's an intake in the front to collect balls from the floor but the robot was most efficient (and less likely to be exposed to damage by other robots) when fed by the human player directly into the hopper. The drivetrain is mecanum so we got pushed around a bit but we compensated by changing the gearbox gear ratios after our first district event. We gained more speed and had less torque - but you had to catch us first before you could push us around! The shooter was very capable and could easily shoot over the truss as well hit the upper goals. There is a rear-mounted telescoping blocker - it successfully did a double-block during the autonomous period in one match. The picture shows the robot without its bumpers. Scorpio was retired in 2017; its parts recycled for other robots. |

|

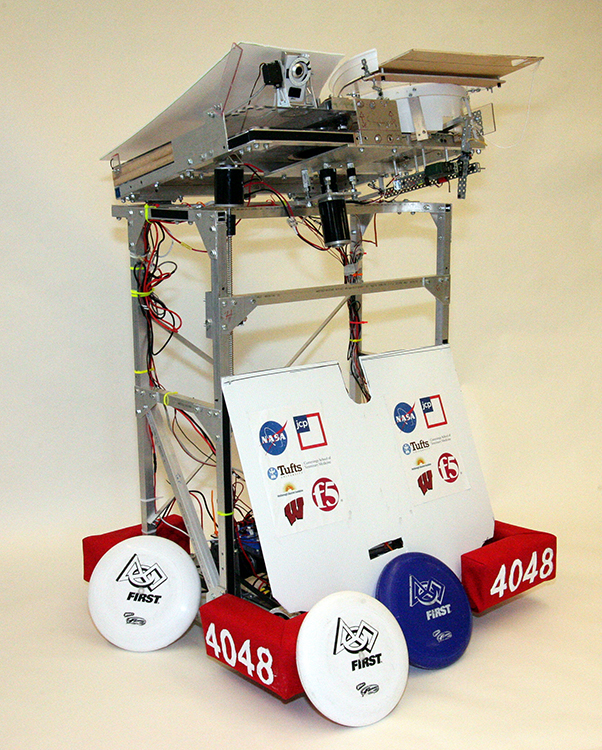

U-turn, Ultimate Ascent, 2013

U-turn was a rectangular robot that was slightly wider than long. This made it less stable than desired but allowed us to put a frisbee shooter that still fit within our frame boundary. U-turn had 2 normal wheels in the front and 2 omniwheels in the rear. The shooting head was hinged at the rear and was adjusted via a mini-CIM and threaded rod. The picture shows the original robot with its top mounted frisbee loader (from the human station). In the post-season, 18 inches was lopped off to increase stability and a new loading mechanism was added. The robot could not climb the pyramid. The shooter is a U-shaped (hence its name) mechanism with a center wheel powered by a CIM motor. Since 2013, U-turn has been our best demo robot, having thrown hundreds of frisbees in numerous events. |

|

Kitty, Rebound Rumble, 2012

Kitty was a foam basketball shooting robot. It had a 6-wheel drop center drivetrain powered by four CIM motors. The chassis is the KOP kit plus 80/20 aluminum extrusions. The ball elevator could hold 3 balls but due to the geometry of the parts involved, the last ball in the elevator could not reach the shooting wheel by itself. So you always had to have 2 balls in the system - one to push the other into shooting position. The last ball is wasted. The shooting mechanism consisted of 2 wheels to help center the ball. It was powered by 2 parallel BaneBot motors. The elevator had 3 independent segments - the top 2 are belt driven and the lower segment had an intake roller. To lower the bridges, Kitty had two pneumatic pistons that raise its front end higher than the lip of the bridge. This allowed the driver to place the bumper over the bridge and use the weight of the robot to lower the bridge. Kitty was retired in 2014; its parts recycled for other robots. |